2.3 Minimising our Impact

on the Environment & Biodiversity

Non-GHG Emissions, Waste & Pollution

Reducing non-GHG emissions

We measure and closely monitor NOx, SOx and Particulate Matter emissions from our vessels in compliance with MARPOL.

Despite our sailed distances increasing in 2022 by 26.3%. Hafina managed to reduce our NOx intensity by 21.5%, and our SOx intensity by 20.0%.

|

Parameter & Units

|

2022 VS 2021

|

2022 | 2021 | 2020 |

|

Number of vessels included in emission calculation for the year |

+ 39.8% |

123* |

88 |

89 |

|

Distance sailed – NM |

+ 26.3% |

5,948,844 |

4,711,326 |

4,549,692 |

|

NOx emissions

|

||||

|

gms/DWT-NM |

-21.5% |

0.22 |

0.28 |

0.30 |

|

MT |

+3.4% |

79,162 |

76,528 |

77,724 |

|

SOx emissions

|

||||

|

gms/DWT-NM |

-20.0% |

0.01423 |

0.01780 |

0.02 |

|

MT |

+5.4% |

5,078 |

4,819 |

4.906 |

|

Particulate Matter – Black Carbon emissions

|

||||

| gms/DWT-NM |

-3.4% |

0.0004633 |

0.0004795 |

Not reported |

| MT |

+27.4% |

165.31 |

129.79 |

Not reported |

Detail the calculation – Please note: Specific energy of fuels: Residual fuel = 40.2 MJ/kg, distillate fuel = 42.7MJ/kg. (See page 278 of the IMO Fourth GHG study). This is used to calculate kilowatt-hours for NOx emission factors

SOx emission factors: 9.7753*10^-3 mt per mt of residual fuel, and 1.9551*10^-3 mt per mt of distillate fuel. (See page 74 of the IMO Fourth GHG study)

NOx emission factors: main engine (ME) = 14.4g/kWh; auxiliary engines (AE) and cargo diesel engine (CDE) = 10.5g/kWh. (See page 410 of the IMO Fourth GHG Study)

BC emission factors: 60% engine load assumed for ME, AE, and CDE. Main engine (ME) = 1.80*10^-4 mt per mt of residual fuel, and 4.00*10^-5 mt per mt of distillate fuel; auxiliary engines (AE) and cargo diesel engine (CDE) = 4.10*10^-4 mt per mt of residual fuel and 2.10*10^-4 mt per mt of distillate fuel; boilers and inert gas generator = 0.08 mt per mt of residual fuel, and 0.06 mt per mt of distillate fuel (See page 415 of the IMO Fourth GHG Study)

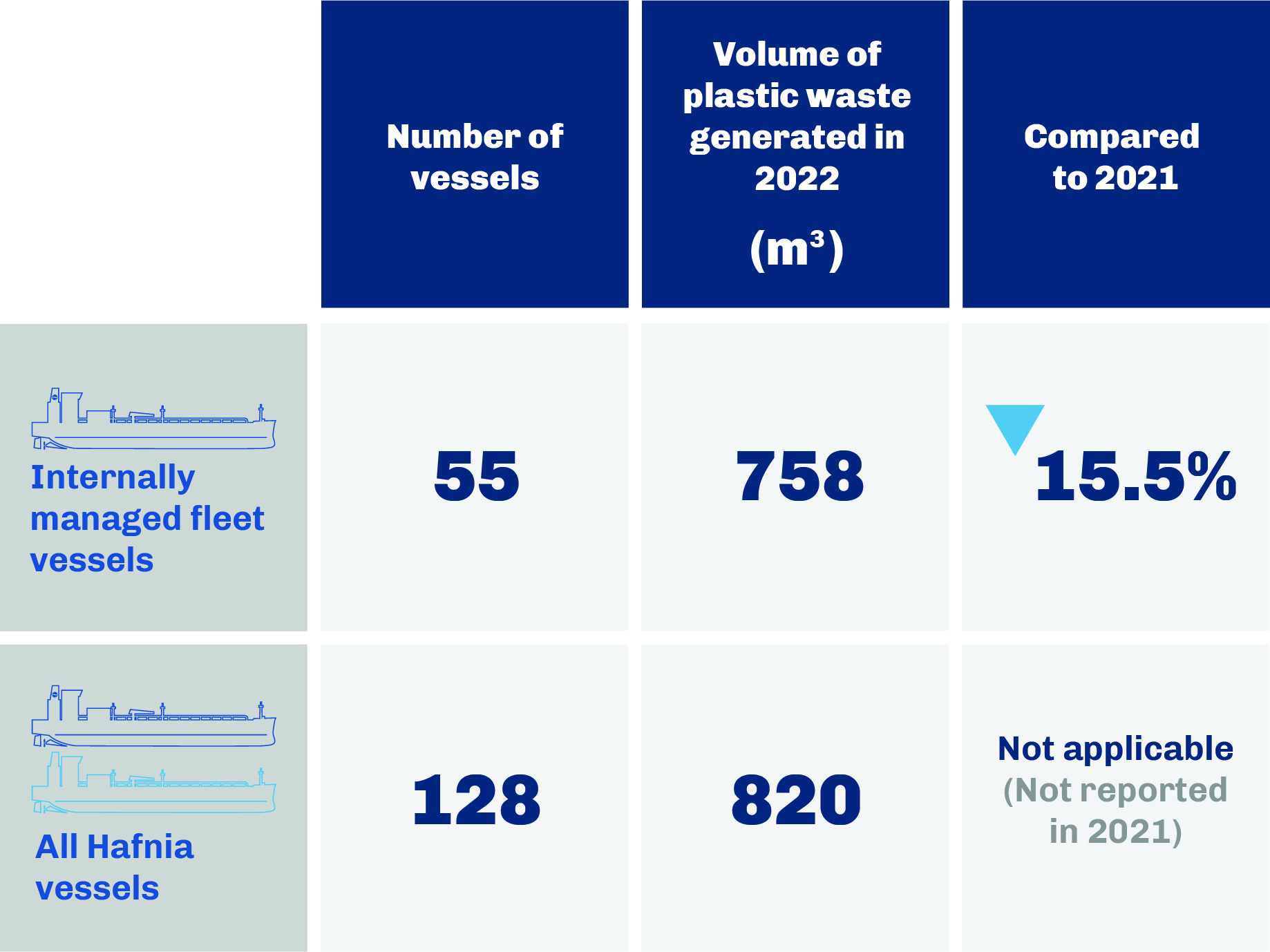

Reduction of plastic and garbage

The use of plastic places huge pressures on marine ecosystems, and we are continually working to reduce the volume of plastic waste created by our operations.

In line with MARPOL Annex V and local regulations for the prevention of pollution by garbage from ships, every vessel in our fleet holds a garbage management plan, which includes written procedures for minimising, collecting, and disposing of garbage, and usage of the equipment on board.

Our procurement team continuously engage with suppliers to avoid and reduce single-use plastic onboard, in returning PVC shrink wraps, plastic carrier bags, and polystyrene foam chips to suppliers.

This plan is verified at regular intervals by Classification Societies and Regulatory Authorities. We contract qualified and licensed third-party vendors to transportand dispose of hazardous waste, who follow strict regulatory tracking, disposal, and reporting requirements as per the local laws.

In 2022, we reduced our overall plastic waste by 15.5% within our internally managed fleet compared to 2021.

All Hafnia vessels hold a management plan that provides instructions on correct disposal of hazardous and non-hazardous waste, approved storage and disposal facilities. This plan is developed with the goal of identifying the quantity and toxicity of waste and increasing the recycling rate when feasible.

This plan is verified at regular intervals by Classification Societies and Regulatory Authorities. We contract qualified and licensed third-party vendors to transport and dispose of hazardous waste, who follow strict regulatory tracking, disposal, and reporting requirements as per the local laws.

Oil Spill Prevention and Response

Amongst all shipowners, oil spills risks exist during cargo, bunkering and ship operations.

At Hafnia, we follow strict protocols and policies to avoid such incidents. These place special emphasis on effective communication, transfer processes, signalling procedures, sampling processes between the ship and barge during bunker operations and response in time of emergency.

On the 28th of July 2022, Hafnia RHINE experienced an unprecedented, first-time bunker spill on the Mississippi River.

An overflow from a bunker vent occurred during bunkering operations where operations ceased immediately. This was quickly followed by containment and cleanup of the overflow, following all recommended protocols in cooperation with all relevant authorities.

Fortunately, no harm was caused to any of our crew and the surrounding environment or wildlife. This incident was taken very seriously, with an in-depth investigation carried out. As a result, Hafnia has reinforced its processes and underlined measures to avoid future recurrences.